PREPARING FOR YOUR ANTIQUE MIRROR

Accurate Measurements Give a Perfect Fit

At Antique Mirror Glass we can provide you with a quote for your Mirror tiles, panels, feature walls and splash-backs.

Ultimately we want your glass to look stunning and to fit perfectly. For any complex spaces, or any areas where panels of Antique Mirror Glass will be set next to each other, we’d recommend asking a professional to complete your final measurements, and provide sizes for each individual piece or panel your require. We are happy to talk through this process with your tradesperson if necessary.

To help you and your builder/carpenter/tiler etc. we’ve created this simple guide to help measure your area. We know that not all walls are perfectly straight or equal, but we can work around this, with your help.

Step One

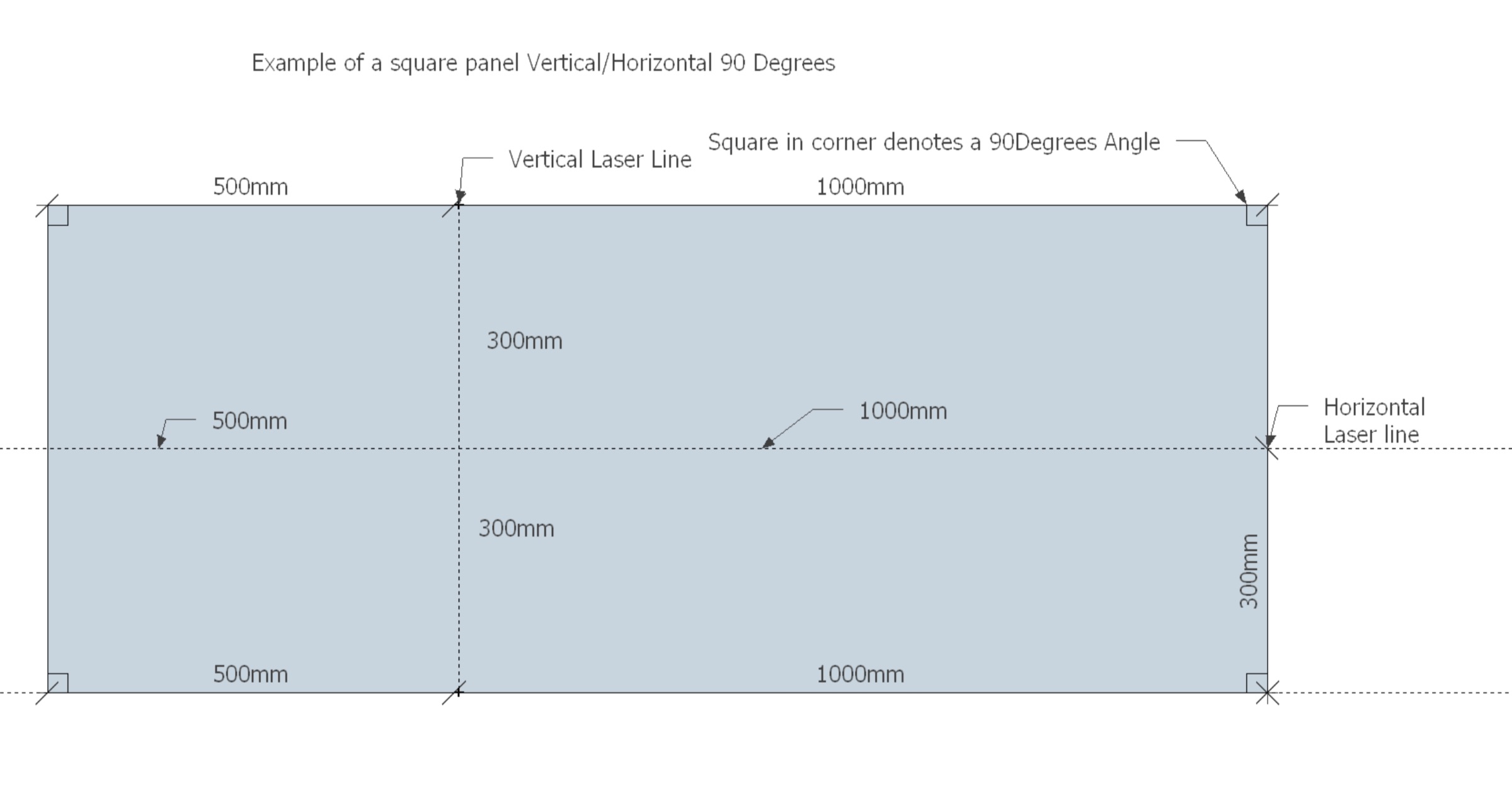

We have used a laser line to pinpoint STRAIGHT vertical and horizontal lines that cross through the area. You could use a spirit level instead, just to ensure the lines are straight. You will need to measure using these straight lines as your guide.

Step 2

Once you have the cross lines you will need to measure each one of the spaces shown in the diagram. We work in millimetres, so please use them too.

Be as accurate as you can and measure all the way to the edge.

We need to know each of these sizes. You can download this form and fill out, or simply sketch up your own and send as an attachment with your request for a quote.

Step 3

Fill in your measurements (in millimetres please) and send through to us with with your chosen finish and your contact and delivery details. We can then send you an accurate quote. Once you place an order we will call you to talk through your project to ensure we understand every detail.

Our tips for

The Perfect Fit

Providing CAD Drawings or a Sketch

We require the measurements of your panels to the nearest millimetre. You can email us a sketch showing dimensions in mm and cutout locations to the centre of the hole/powerpoint or raked edges. (Raked edges - are straight edges on a panel where one or more corners is not a 90 degree right angle. See information below regarding raked edges).

If you are able to provide a CAD drawing for production this would always be our preference. Please email us with both DXF and a PDF copy of your file.

Providing a Template

If providing a template for your design, only MDF or Plywood templates can be accepted, in order to ensure they can be scanned successfully and replicated accurately. No other materials can be used for templates. Templates must be exact to size with no addition or subtraction requirements.

Multiple Panels

We require one template per panel of mirror. We cannot accept a single large template, if you require this to be split into multiple panels, as the template would have to be cut and you would lose the width of the saw blade with each cut, creating 5mm gaps between panels.Cutouts

You can either physically cut out the holes in the templates or mark the centre point of standard socket cutouts on the templates.Edges

Templates should be provided with straight edges, unless there is a definite shape requirement.Internal Cutouts

There will always be a radius corner on any internal cutouts of at least the thickness of the glass. The internal cutouts will have a ground edge rather than a highly polished edge.

Sending Us Your Template:

Please ensure that you mark the template with your NAME & which side is the FACE. Pack it carefully to avoid any damage to the edges or corners in transit.

Send it to:

Antique Mirror Glass

6/8 Grevillea Ave, Byron Bay, NSW 2481

Not All walls are Equal

Here are a few examples of some of the shapes we can work with.

We can work with yours if you help us to understand it.

Click on the image below to expand.